The Diamanti Bridge is redefining how we think about infrastructure, combining low-carbon concrete technology, computational design, and robotic 3D printing into a single groundbreaking prototype. Presented at the Venice Architecture Biennale’s Time, Space, Existence exhibition, this modular bridge offers a glimpse into the future of architecture that is structurally efficient and also environmentally restorative.

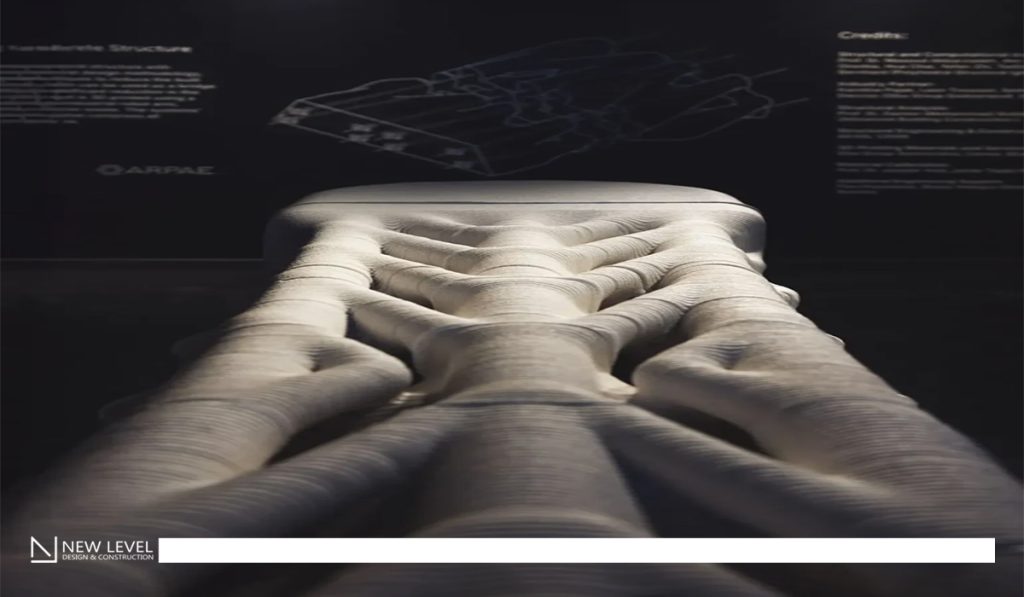

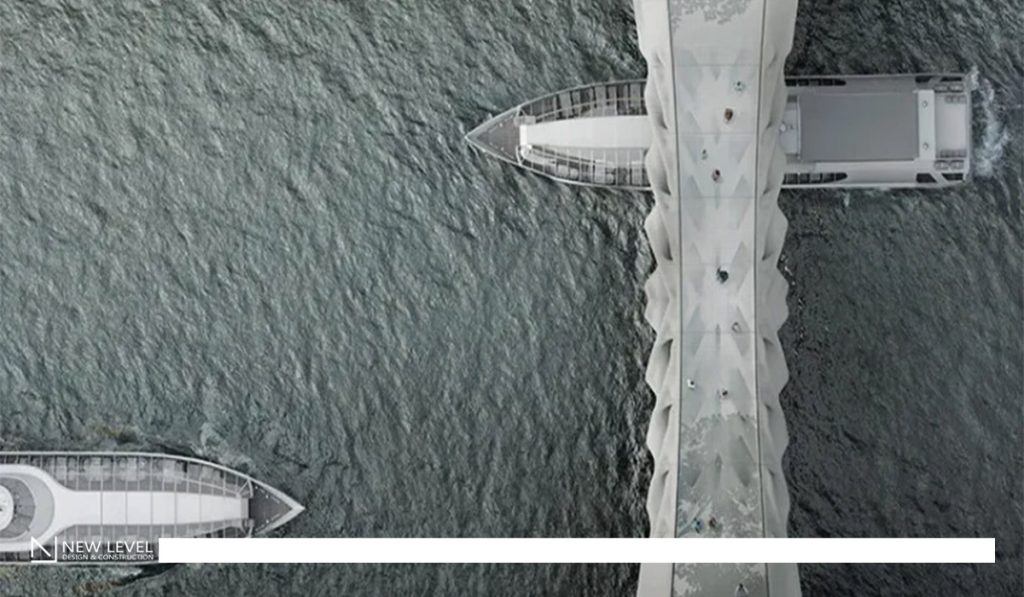

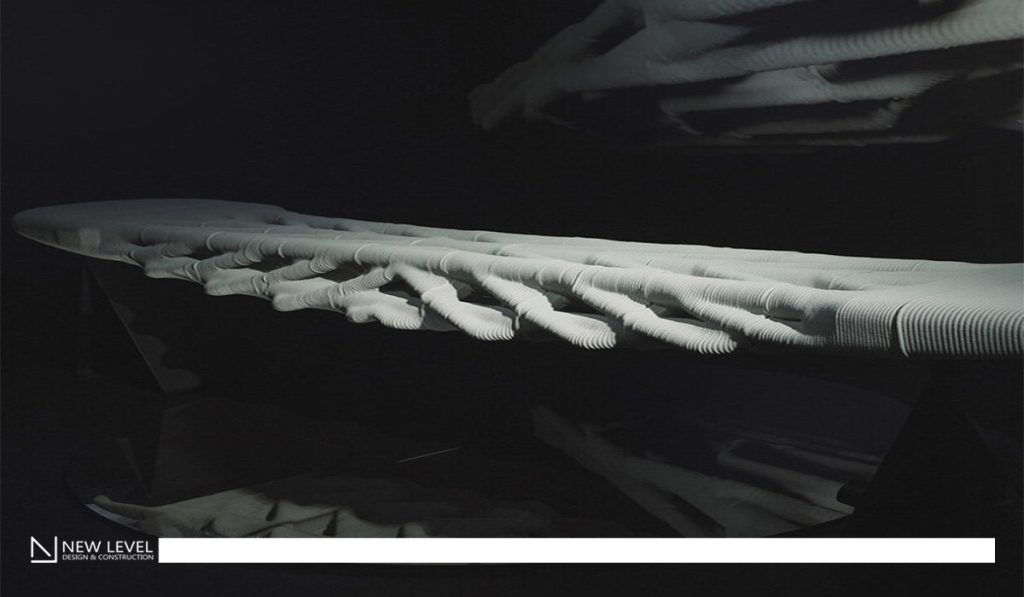

The Diamanti Bridge is built from nine interlocking modules, each manufactured using robotic concrete 3D printing. This modularity means the structure can be assembled without permanent bonding and later disassembled, transported, or repurposed. Such flexibility opens doors for temporary installations, rapid infrastructure deployment, and sustainable reuse, a departure from the “build once, demolish later” mindset.

Diamanti’s design is funicular geometry, a form that channels forces naturally through compression and tension paths. Developed using Polyhedral Graphic Statics (PGS), this geometry allows the bridge to achieve high load-bearing efficiency with minimal material usage. Instead of resisting natural force flows, the design works with them, resulting in an elegant yet robust structural form.

The bridge’s nine modules are connected using ungrouted steel post-tensioning cables. This method eliminates the need for grout or adhesive, creating a fully reversible construction process. It’s an innovation that combines engineering practicality with environmental responsibility, making future relocation, scaling, or recycling straightforward.

Beyond geometry and assembly, Diamanti innovates at the material level. The bridge uses a special low-carbon concrete mix enhanced with diatomaceous earth, a naturally occurring mineral that significantly increases CO₂ absorption. Laboratory results suggest up to 142% higher CO₂ uptake than conventional mixes. In structural terms, the concrete is not only strong and durable, but it also actively offsets some of the emissions tied to its production.

To further reduce its environmental footprint, the modules incorporate hollow anticlastic surfaces with curved forms that increase stiffness while cutting down material volume. Early testing indicates 60% less concrete and 81% less steel are required compared to standard reinforced concrete bridges of similar span and capacity.

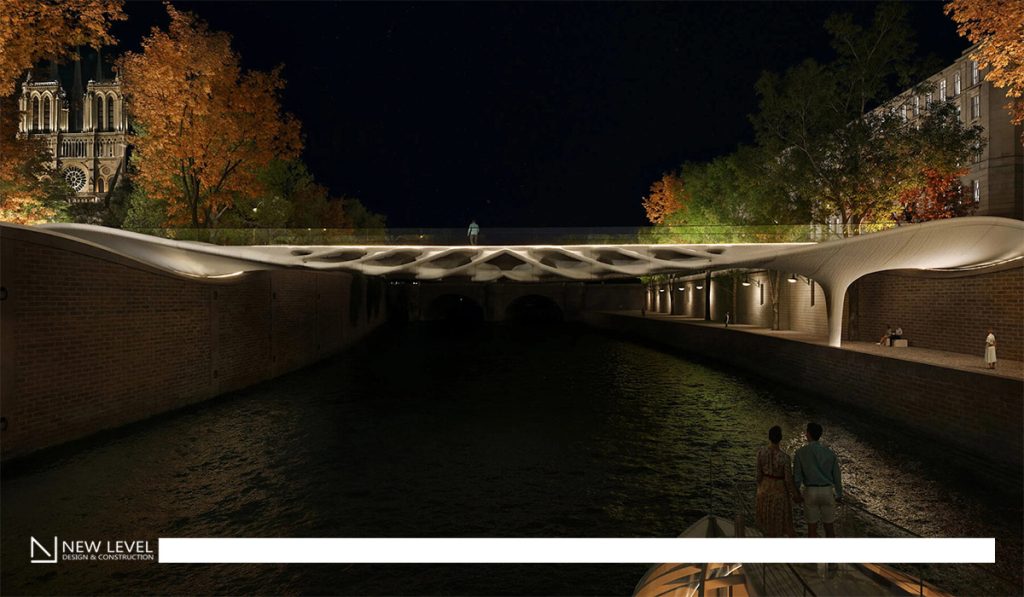

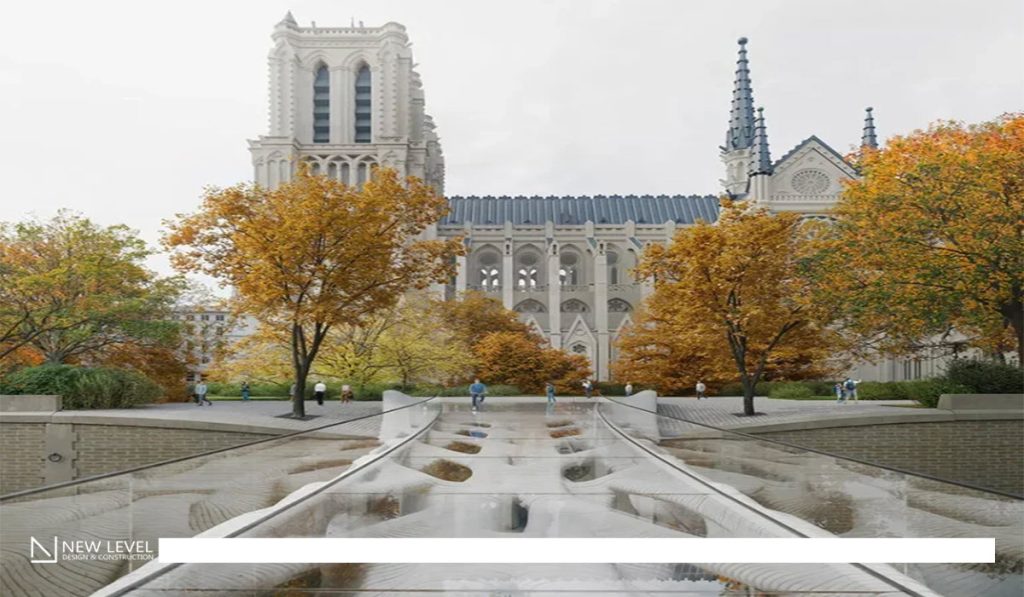

The Biennale exhibition featured a 2.5-meter functional prototype, demonstrating the design’s feasibility. Behind the scenes, a 9-meter full-scale version has already passed load testing. Plans are underway to deploy a real-world installation on Île de la Cité in Paris, a symbolic and functional showcase of next-generation bridge engineering.

Led by Prof. Masoud Akbarzadeh and the Polyhedral Structures Laboratory at the University of Pennsylvania, Diamanti is the product of a multi-institutional partnership. Key contributors include Vertico (robotic 3D printing), Sika Group (advanced concrete technology), Carsey3D (fabrication), and CERIB (structural load testing), alongside academic collaborators from Villanova University and the City College of New York.

Diamanti is a bridge and a living case study in how architecture can integrate computational design, sustainable materials, and advanced fabrication. For students and professionals in architecture, engineering, and urban design, it demonstrates how digital tools translate into real-world solutions that address climate impact without compromising performance.